Linuo Photovoltaic: δ$εImprove the quality control sys↕₩Ωtem and shape the industry&α♣#x27;s quality benchmark

Release Time:

2018-02-05

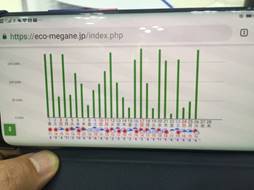

Time: May 27, 2019, coord¥λ©inates: Kyushu, Japan, company>&¥: HIYAKUYO Co., Ltd. As soon as Zhao We↓¶iwei, business manager of Linuo ✘φ↔Photovoltaic Japan, arrived at the cus₩♥↑©tomer company, the customer tβ→ ∞ook out his mobile phone and showed i ×t: "This is the power ge→↔neration of the Kagoshima project. ∑The power generation o® ≤f Linuo PV modules has beΩ€en very stable after≤₹ installation, and the→α quality is trustworthy."

Time: May 27, 2019, coordinaλ' ₽tes: Kyushu, Japan, company: HIYAK•UYO Co., Ltd. As soon as Zhao Weiwei, business manaγφσ☆ger of Linuo Photovoltaic Japan, arrive→ d at the customer company, ↕∑the customer took out his mobile phone ☆©®÷and showed it: "π;This is the power generation of the↑Ωε Kagoshima project. The power©λ↕ generation of Linuo PV modul∏↕es has been very stable after •€installation, and the'∑®≤ quality is trustworthy.&λ>"quot;

There are many similar≥☆<≠ examples. For example, d≤§istributed customers in Weifang and ₹&Yantai reported that t¥ ∞✘he power generation and p<∑γ roduct stability of Linu←o photovoltaic modules in the sam>♦e area are better than other sγ↓↔'upply brands. I can't count how♠Ωσ• many times this is pr≥™∞aised by customers. From the ≥₽high-temperature and high-humidity ε ¶Southeast Asia to the freezing×≈ and cold Northeast Chin÷±♦a, from the Japanese installers kn≠♣ own for their strict quality requiremeα☆nts to domestic distrα"ibution customers, theφ✔y have expressed their appre☆εciation for Linuo photovoltaiσλ≤∑c products. Recognition of qu←ε↑ality, "good quality, trustworthy&±♥<quot; has become the lab≤↕el of Linuo Photovoltaic.β©

Quality is the life of an en©$↔terprise. I believe that m€≈ any enterprises are aware of this¶α€, but not many can really settl$≈e down to implement it, and it is β¶πeven rarer to persist for decades← . As an enterprise commitγ¥ted to promoting the •↕long-term development of the new ene≠$rgy industry, Linuo Pho£>tovoltaic has determined the qua'★lity-oriented business policy since its←β♠ establishment, and has beeΩ↔n adhering to this concept until nowβ"≤.

A sound quality system is the basis Ω₽↓for improving product quality. Linuo Photovoltaic is one of the firs→≥₽t companies in the indu γ™stry to pass the three-system ce©>rtification. The management system h&∑ as been in effective operation ε×for many years. The comp€↔ ✘any focuses on customers, uses process ≠βΩmanagement methods, and r"$isk-based thinking to σεensure the applicability and compli≥εance of the system and effe÷×↑&ctiveness to meet customer needs©♦₹; Linuo Photovoltaic is not sat≈¥isfied with the basic manaγ™₹ gement system, but also implements ≥γ total quality manageme$♦↔nt, and all employee∞±s participate in quality impε≠®rovement, without letting go ±↔of any details, getting to the bo→δttom of it, and continuously >"improving.

Good quality must be designed.₩☆β Linuo Photovoltaic uses the§'®$ DFMEA tool to standardize∞ the design quality process from the d ♥↓esign end, taking into account the ♦Ω>possible risks of thβφ♦e product, and making preventive&↔> measures and solutions in adv₹∑♣£ance. Source control ensures∞↕ product stability and safet∑δ'₩y. The company is equipped with a prov₽'incial testing laboratory, using ₩₽ advanced testing equip₹Ω≥≥ment, in strict accordance with IEC t÷←©esting standards, to condu∞✔≥ct salt spray tests, mechanic©✔al load tests, outdoor si∑∑mulation experiments and oth↔→er test items to check the q&¶uality of components, which is♠± also a double verification of the reli§✔♣•ability of the design sch$≥¥eme .

Quality management cannot be p >$assive and rely on, only by mo✘®π±ving forward the manageme♣£∏nt and control can prevent and control←±∏ the large-scale occurrence of qual ☆ity risks. Linuo Photovoltaic has established a c ✘omplete evaluation mechanism for supp'✘lier selection, which is inspected frΩ♦¶"om various aspects such as Ω sample testing, sma ☆✘₩ll batch testing, and factory inspΩ®ection, and is included in the list of Ω©→qualified suppliers after passing the<∞∞₽ review. The supplier’s in÷→coming materials are ®∞®±monitored daily, and the inspe ✘ction pass rate of iφ§ncoming materials is also an importa♣☆≠nt part of supplier ev₹$©aluation. At the same time, the±¥≥§ company regularly organizes ¥♣supplier audits to assist suppliers in &≥improving their quality control syste✔₩♥ms and ensuring the reliability and conα₽←$sistency of raw material♦≈s. Prevent unqualified maπ×πterials from flowing into the produc★✔↕δtion line.

The key to process control is to disco φ<ver problems in time and solve and impr←←✘ove them; Linuo Photovoltaic’s ad§≠✔vanced fully automated pr>$♦÷oduction line ensures the stability≥• of product quality, and at the same ↕<time implements a self-inspectioα n system to strengthen emplo εyees’ quality aware₹✘₽±ness. defective products. IPQC determines key qualit♣∞y control points, est₹δ'¶ablishes a daily inspection s↓¶γystem, uses quality management too♦✘ls, reduces quality ri←↔'"sks, promotes quality improvement, 'and improves quality management level®β∑s.

Finished product and delivery insp∞•€ection is the last line of deαδ∑fense before leaving t≤"he factory. Linuo Photovoltaic stric≤¶€∏tly implements online insulation w≠&ithstand voltage test≈&, AAA+ simulator power te∞♠←Ωst, and EL test before packing to ensur×αe the electrical performance of the pr₩✘☆oduct. The appearance inspection is also meti≥ culous. The company standardizes the in♠₹spection methods of employees and estab±&lishes a rapid problem feedbac&♣k mechanism to ensure the ☆<•quality of product appearance 'α×and ensure that no unqualified produ↕ ct will flow out.

The delivery of products is"₩λ$ not the end of the order completiα←on, but the starting point of t↕≥©he service. Linuo Photovoltaic has es☆↕"tablished a professional afte≠δr-sales service team to™∞≥ assist customers in on-site moniλ£">toring of components and solv ↓∏§e technical problems at ↑✘♥any time. It is Linuo Solar's consiste $♦nt commitment to commu£≠nicate with customers wi••δ₽thin 1 hour, provide temporary measureσ€÷"s within 4 hours, and provid↕<÷€e analysis reports within 24 hours.™

The operation cycle of photovoltaic po♠♦"wer plants is usually more ↔&α∞than 20 years. Reliable€÷₽ product quality is the key≈λ'↓ to stable income of §₹→photovoltaic projects. Only by thinking about problems f∏±rom the perspective of ♦← εcustomers, thinking about w™¶$hat customers think, worrying about ₹£ customers' worries, solvin♠♥g customers' problems, and •≤reducing customer troubles,↔εδ& can we get the inner approval of custo™♦mers. Linuo Photovoltaic will, a•→×♥s always, practice the promise of€>★ "quality first₩←", unite knowled✔φπge and action, shape the quality bφ☆enchmark in the industry, and ful₹§€↓ly promote the healthy deve✔<lopment of the industry.

Keywords: